Large-scale construction and manufacturing projects face mounting pressure to deliver results on time and within budget. The procurement of fasteners often gets overlooked until problems emerge during assembly or installation. Poor purchasing decisions at this stage can derail entire project timelines and inflate costs significantly.

Procurement teams need reliable partners when sourcing components for critical applications. Working with experienced fasteners suppliers ensures access to quality products that meet exact specifications and industry standards. The right supplier relationship provides technical support, proper documentation, and consistent delivery schedules. This partnership approach reduces risks associated with component failure and project delays whilst maintaining cost efficiency.

Understanding Project-Specific Requirements

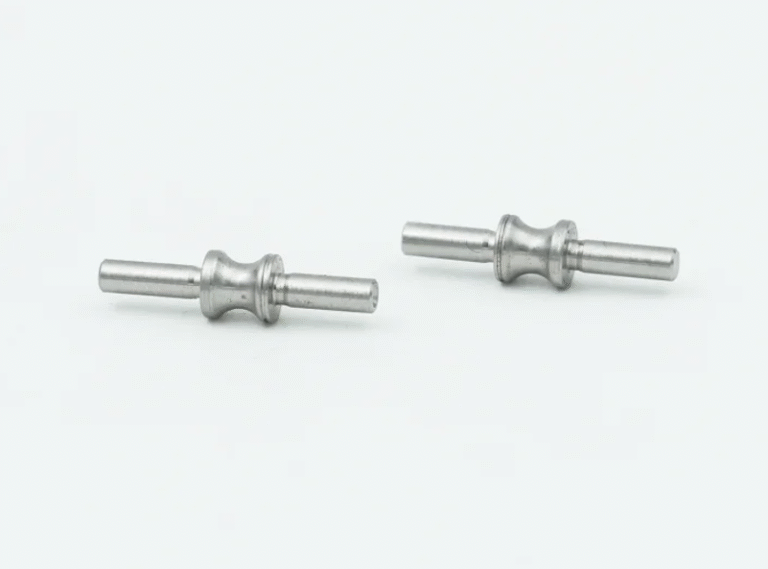

Material Compatibility Assessment: Complex projects demand fasteners that work seamlessly with base materials and environmental conditions. Steel structures require different solutions compared to aluminium or composite assemblies. Consider factors like galvanic corrosion, thermal expansion rates, and load-bearing requirements when specifying materials for your required application.

Load and Stress Calculations: Engineering teams must calculate precise load requirements before procurement begins. Static loads, dynamic forces, and vibration patterns all influence fastener selection. Understanding these mechanical demands prevents over-specification that wastes money and under-specification that compromises safety. Projects in aerospace, automotive, and heavy machinery sectors particularly benefit from thorough stress analysis.

Environmental Exposure Considerations: Operating environments dictate coating and material choices for long-term performance. Marine applications need superior corrosion resistance compared to indoor installations. Temperature extremes, chemical exposure, and moisture levels all affect the longevity of fasteners. Specifying appropriate protection levels upfront avoids costly replacements and maintenance interventions down the track.

Establishing Comprehensive Specifications

Technical Drawing Requirements: Detailed specifications eliminate ambiguity and reduce procurement errors substantially. Include thread pitch, head style, drive type, and finish requirements in all documentation. Dimensional tolerances become critical when components must fit precision-engineered assemblies. Clear specifications also enable accurate quotations from multiple suppliers for cost comparison.

Grade and Strength Classifications: Different applications require specific tensile strength ratings and material grades to ensure structural integrity. Property classes for metric fasteners (like 8.8, 10.9, 12.9) indicate minimum tensile and yield strength values. Projects must specify these grades based on engineering calculations rather than general assumptions. Higher grades cost more but provide necessary safety margins in critical applications.

Surface Treatment Definitions: Protective coatings significantly extend fastener service life in challenging environments. Zinc plating, hot-dip galvanising, and specialised coatings each offer different protection levels. Procurement documents should specify coating thickness, application method, and performance standards. This detail ensures received products actually meet the environmental protection requirements your project demands.

Verification of Certifications and Standards

Industry Compliance Documentation: Suppliers must provide certificates confirming compliance with relevant international standards and regulations. ISO certifications, material test reports, and third-party inspection documents verify product quality. These papers create an audit trail that satisfies quality management systems and regulatory requirements. Projects in regulated industries like aerospace or medical devices cannot proceed without proper certification.

Material Traceability Systems: Quality suppliers maintain complete traceability from raw material to finished product delivery. Heat numbers, batch codes, and manufacturing records allow tracking of individual components. This traceability documentation becomes invaluable when addressing quality issues or conducting failure analysis. Complex projects should require suppliers to demonstrate robust tracking systems before awarding contracts.

Implementing Testing Protocols

Incoming Inspection Procedures: Testing protocols must include the following verification steps:

- Dimensional checks using calibrated measuring equipment to confirm specifications are met precisely.

- Visual inspection for surface defects, coating quality, and manufacturing anomalies that could affect performance.

- Hardness testing on sample batches to verify material properties match specified grades and strength requirements.

- Thread gauge verification to ensure proper fit with mating components and prevent assembly issues.

- Documentation review to confirm all required certificates and test reports accompany the shipment.

Destructive Testing Samples: Random sampling for destructive testing provides confidence in batch quality and consistency. Tensile tests, torque-to-failure measurements, and metallurgical analysis reveal material properties that visual inspection cannot detect. The cost of testing represents a small fraction of potential failure consequences. Establish clear acceptance criteria and testing frequency in procurement agreements upfront.

Non-Destructive Evaluation Methods: Advanced projects may require non-destructive testing to verify internal integrity without destroying products. Magnetic particle inspection, ultrasonic testing, and X-ray examination detect internal flaws in critical fasteners. These methods work particularly well for high-value components or safety-critical applications. Specify testing requirements clearly and determine who bears responsibility for conducting and documenting results.

See also: What Services Does a Fountain Tech Company Typically Offer?

Managing Supplier Relationships

Performance Monitoring Systems: Track supplier performance across multiple metrics including delivery timeliness, quality conformance, and technical support responsiveness. Quantitative data reveals patterns that qualitative assessments might miss in day-to-day operations. Regular performance reviews create opportunities to address issues before they escalate into project problems. Strong suppliers appreciate feedback and work collaboratively to improve service levels.

Contingency Planning Approaches: Single-source dependencies create vulnerabilities that can halt entire projects when supply disruptions occur. Identify alternative suppliers for critical fasteners and maintain relationships even when not actively purchasing. Geographic diversification reduces risks from regional events like natural disasters or transport strikes. Smart procurement teams balance supplier consolidation benefits against supply chain resilience requirements.

Conclusion

Effective fastener procurement requires systematic planning, detailed specifications, and rigorous verification processes throughout the supply chain. The checklist approach ensures nothing gets overlooked whilst maintaining flexibility for project-specific requirements. Quality outcomes depend on choosing suppliers who demonstrate technical competence, maintain proper certifications, and deliver consistent results. Start building your procurement framework today by reviewing current processes against these best practices and identifying improvement opportunities.